There are many indicators on the dashboard of a modern car, but the fuel pressure indicator is not among them. Although this parameter directly affects the performance of the engine. And if you think that everything is not all right with this indicator, you need to measure the fuel pressure manually. We have prepared instructions on how to do this: the procedure is not very complicated.

Why fuel line pressure is important

For an internal combustion engine to work efficiently, it needs a stoichiometric mixture of fuel and air. This complex term means that there must be exactly the right amount of oxidizer (in this case, oxygen in the air) to burn the right mass of fuel. The stoichiometric mixture for gasoline is one part gasoline to 14.7 parts air.

The amount of gasoline supplied is regulated by the opening time of the injector valves. The ECU unit, having calculated the optimal composition of the mixture, gives the appropriate command to each injector. But the amount of fuel entering the cylinder, in addition to time, depends on the pressure under which it will be injected.

That is, the ECU program already has a normal working pressure, and if its real value is less, the injector will give out less fuel. Hence, at least loss of traction. That is why it is so important that the pressure in the fuel rail was exactly as it was provided by the designers.

When it is worth measuring the pressure

Low pressure in the fuel line always makes itself known. In particular, it is worth paying attention to such problems:

- The engine starts and stalls.

- It takes a long time to crank the starter to start the engine.

- The car does not accelerate as dynamically as before.

- When you press the throttle, the engine does not gain speed, does it slowly or even stalls.

Of course, the same symptoms are characteristic of a number of other malfunctions, so it is always better to start with the least expensive diagnostics.

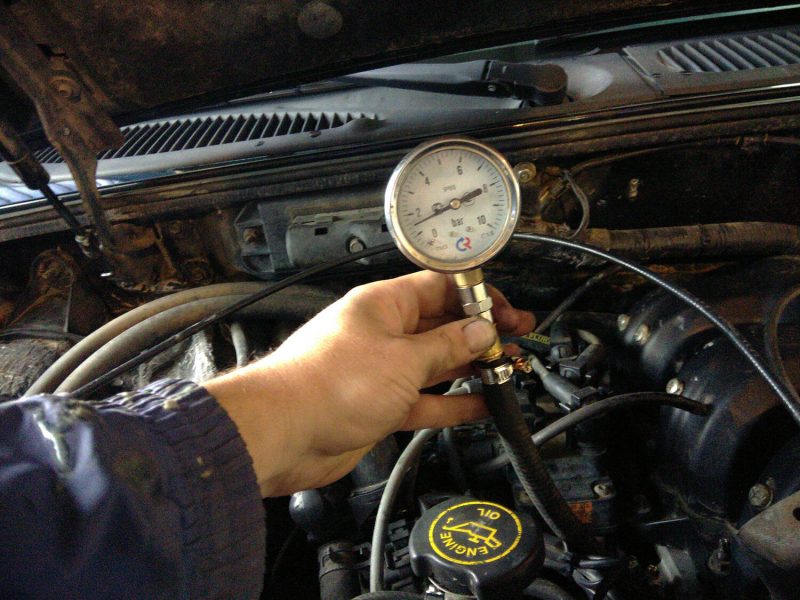

Is it difficult to measure the pressure yourself

To check the fuel pressure in the ramp you will need a minimum of devices and tools. You will also have to disconnect the fuel supply hose: at this point, as a rule, a small amount of gasoline is spilled, so it is worth stocking up on napkins or rags to keep the engine compartment clean. Many people do not know what kind of gauge to measure fuel pressure in the ramp, and use, for example, a tire gauge. In a critical situation, it will be fine, but it is better to use a special device. It costs not very expensive: about 20$ as of the end of 2023.

On modern cars, the fuel line is attached to the ramp with quick-release connections. If this is the option you have, you won’t even need a tool. In older cars, you will have to unscrew the clamps, so you will need a small screwdriver.

It is also worth checking the working pressure in your car’s system. The exact value is usually given in the service documentation.

How to Check Fuel System Pressure

Here are step-by-step instructions on how to measure fuel pressure:

- First it is desirable to depressurize the main line to reduce the “fountain” of fuel when disconnecting the hose. To do this, you can take out the fuse circuit of the fuel pump standing in the tank, start the engine and wait until it stalls.

- Then turn off the ignition, disconnect the hose from the ramp and connect it to the pressure gauge (in old cars – with a fitting and a clamp).

- Connect the fuel pump back (it is necessary to put the fuse in place)

- Turn on the ignition and look at the readings of the pressure gauge. In a serviceable system of a modern gasoline car with distributed injection should be from 3 to 5 atm.

- Before disconnecting the pressure gauge, you need to reset the pressure again. For this purpose, such devices have a special valve and a thin plastic tube. You need to put a container, put the tube in it, press the valve and wait for the gasoline to drain.

- Then disconnect the device and connect the hose to the ramp.

To measure the pressure in the fuel system, there are also “pass-through” gauges. They are included in the cut between the hose and the ramp. The advantage of such a model is that you can observe the pressure during engine operation – it must remain constant.

What to do if the pressure was insufficient

If checking the pressure in the fuel system showed that there are problems with it, you need to understand their nature. To do this, it is desirable to record everything that happens on the device during diagnosis. Here are the possible scenarios:

- There is no pressure at all, or it is very low. As a rule, the fuel pump is to blame. It will most likely need to be replaced.

- The pressure gradually (but slowly) builds up to operating pressure. Usually, such a picture indicates contamination of filters: the mesh filter in the gasoline pump housing or the fine filter on the line itself. The latter is not difficult to replace, but to assess the condition of the “mesh” will have to remove the fuel pump, and this is not always easy.

- The pressure is kept stably low or gradually resets after turning off the ignition. These can be signs of a faulty fuel pressure regulator (FPR). If the pressure drops, it is also worth checking the entire line for leaks. Sometimes the fuel injectors also “leak”.

How to check the fuel pressure regulator

Most often, problems arise precisely because of the RDT. These sensors come in two designs. The simplest (found on very low-cost and just old cars) is mechanical. Such a sensor has three leads for fuel and a spring with a diaphragm inside. As long as the pressure is normal, fuel flows through the RDT, nothing holds it back. If it is higher than necessary, the valve with a diaphragm opens, and fuel flows through the return line from the third outlet of the sensor back into the tank.

It is possible to check the serviceability of such a sensor by simply squeezing the “return”. If the pressure is normal, the RDT is defective. If you do not know where the fuel pressure regulator is located, look for it on the fuel ramp (the pipe connecting the injectors) closer to the intake manifold.

Modern cars use a more advanced design. In them, the diaphragm interacts with strain gauges, and the ECU monitors the voltage on them and gives a command to the fuel pump to reduce or increase fuel supply. Such RTDs can be checked with a multimeter:

- Switch the device to the DC voltage measurement mode.

- Connect the black wire of the multimeter to the “minus” of the battery, and the red wire to the signal wire (usually it is located in the center of the block).

- Start the engine and let it idle for about a minute.

- See what voltage the gauge shows – it should be about 1.3V.

- Now ask a helper to turn the engine off. The voltage should rise to 4-5V.

- If the voltage rises, most likely, the fuel pressure sensor is good. If not, you need to replace it with a new one.

Totals

- Fuel pressure can not be tracked by indicators or instruments on the dashboard.

- It is better to buy a special pressure gauge to measure the pressure.

- When measuring, pay attention to the character of pressure rise or fall – it will help to understand what may be the problem.

- Normal pressure in gasoline engines with distributed injection is from 3 to 5 atm.